The food safety and quality manual represents the documented system of management for a food manufacturer. It is the framework of management that governs all operational processes. In this post, we’ll explore the composition of a food safety and quality manual and how to make sure it is properly integrated into operational processes.

As we dive into the topic, you’ll be interested to know that Food Industry Hub offers integrated management systems for food manufacturers, with a complete solution for document control and collation of the quality manual, included as part of a holistic package.

Table of Contents

○ Definition: The Quality Manual

○ Collating Every Type of Management Document – From Policies, Procedures, and Work Instructions, Through Reference Documents and Position Statements

○ What Are Policies, Procedures, and Work Instructions – and How Do They Compare With Each Other?

○ Aligning Operations with the Documented Requirements and Expectations of The Quality Manual

○ Making The Quality Manual Accessible to All Staff

○ Advantages of Digital Systems for Document Control

○ Accessibility, Legibility, and Overcoming Language Barriers

○ Designing Training Programs Around Your Quality Manual

○ Outlining Record-Keeping Systems Within the Quality Manual

○ Evaluating Suitability: Is Your Quality Manual Fit for Purpose?

○ FAQ

○ In Summary

Definition: The Quality Manual

The quality manual is a documented system that outlines an organisation’s quality management principles and policies geared towards the achievement of safe food of the appropriate quality. The document provides guidance and instructions as to the organisation’s processes, procedures, and responsibilities for maintaining high-quality standards. The manual also serves as a reference point for internal audits to ensure compliance with regulatory standards and internal processes.

Implementing a robust food safety and quality manual is fundamental to ensuring that an organisation operates safely while producing high-quality products. Through proper documentation of processes and procedures alongside regular audits to identify areas of improvement or non-compliance issues promptly can help maintain consistency in operations while reducing risks associated with unsafe practices.

Collating Every Type of Management Document – From Policies, Procedures, and Work Instructions, Through Reference Documents and Position Statements

The food safety and quality manual is a comprehensive set of documents made up of the policies, procedures, and work instructions the site enlists to ensure that food products are safe for consumption. It should also include reference documents and position statements that provide guidance on best practices for maintaining food safety and quality.

The purpose of collating every type of management document is to ensure that all necessary information is included in the manual. You can think of this as the operating manual for the business – detailing what should be done, under what circumstances, how, and when.

For any process which directly or indirectly influences food safety and quality, an employee carrying out that process should be able to reference the quality manual for a comprehensive explanation for how to undertake the activity.

Collating all management documents into a unified quality manual can bring numerous advantages to businesses, especially those operating in the food industry. First and foremost, it helps standardise processes, procedures, and policies throughout the organisation. This means that everyone is on the same page when it comes to how things should be done, resulting in fewer errors and inconsistencies.

Another advantage of a unified quality manual is that it allows for easy access to information. All relevant documents are collated in one place, making it easier for employees to find what they need quickly and efficiently. Having a centralised documented management system promotes good practice by providing clarity to employees over the practical steps to take when performing tasks. It allows for many people to be trained to approach processes in the same way and enables businesses to audit and review the documented processes.

A well-structured quality manual can also improve communication across different departments within an organisation. It provides clarity on roles and responsibilities as well as expectations of each department. By unifying all management documents into one comprehensive manual, businesses can create a more efficient workflow while ensuring food safety standards are maintained at every step of the process.

Creating a documented quality manual that integrates cross-functional processes can enable people to understand how the activity they are involved with forms part of a larger system of processes – and how any risks introduced could affect downstream activities.

Sign-up for the Food Industry Hub Mail Service

We regularly produce new content for food industry professionals, and the Food Industry Hub Mail Service is the best way to stay up to date with the latest additions.

Signup today to be added to the Food Industry Hub mailing list.

What Are Policies, Procedures, and Work Instructions – and How Do They Compare With Each Other?

Policies provide direction and guidance for decision-making within an organisation. Procedures outline the step-by-step process for completing a specific task or activity. Work instructions provide detailed information on how to perform a specific job or task.

Policies are broad statements that guide decision-making within an organisation. For example, the policy for food safety, legality, authenticity, and quality might state the company’s intention to uphold its commitment to food safety, legality, authenticity, and quality ideals, but may not detail exactly how that commitment would be upheld. The specific mechanisms would be detailed in associated procedures, work instructions, etc.

Procedures are more detailed than policies and outline the step-by-step process for completing a specific task or activity. For example, a procedure may the requirements for personal hygiene, including PPE requirements, reference to the changing work instruction or SOP (standard operating procedure), requirements that apply to specific circumstances, reference to monitoring and verification processes, etc. A procedure outlines the framework of systems and management interventions that are activated in order to satisfy the intent of the policy.

Work instructions provide detailed information on how to perform a specific job or task. They typically include diagrams, pictures, and step-by-step instructions to ensure consistency in performance across different shifts and employees. For example, work instructions may detail how to assemble packaging materials for finished products before they leave the facility.

Work instructions can be used to provide detailed instructions for how to carry out any function, whether or not there is physical work involved. For example, a company might use a work instruction to detail specific steps, and role-holders who should be informed, when a food safety hazard is escalated for managerial attention. Organisationally, there are a lot of benefits because work instructions can be used to define expectations for assurance processes (such as fault reporting), and enable these expectations to be delivered to relevant individuals – with training records confirming that understanding.

Bringing together these documents into the site’s quality manual forms a structure of management processes that govern the operations of the business. Any role-holder from an operative in the factory through to the managing director/chief executive officer should be able to look to the quality manual for guidance on actions and decision.

Policies express the intent of the business, or the stance it takes on particular issues. For the purposes of food safety and quality culture, policies are the documented values that the business has committed to. In cases where managerial decisions have to be made, those decisions should be aligned with the policies.

Procedures structure systems around processes – so a procedure might define sequentially the stages of a process, and make reference to associated work instructions, schedules, etc. They say what must happen, and how it is controlled.

Work instructions serve to standardise the way specific activities are undertaken. They can be used to ensure explicit understanding of how to do something.

There is a hierarchy to the different documents that make up the quality manual. Policies state ideals to be pointed to. Procedures govern processes for the satisfaction of the values documented in the policies. Work instructions govern tasks or activities that contribute to the processes governed by the procedures.

Aligning Operations with the Documented Requirements and Expectations of The Quality Manual

The documented requirements and expectations of the quality manual must be clearly defined, consistently applied, and regularly reviewed in order to have practical relevance.

The documented structure of management represented by the quality manual should be an active and present authority throughout the site’s operations. The ideal position would be for there to be perfect alignment between the expectations of the quality manual and the actions and decisions taken by everyone throughout the business.

Some food manufacturers face a situation where the quality manual exists as a collation of policies and procedures, but is not practically implemented throughout operations. This can happen in a number of ways, so for example a company might have its quality manual written and controlled by the technical department, while the technical department is completely unaware that the production department has introduced a separate collection of training documents – or a more informal system of management can emerge, with people leaning how to do things from the people around them.

You might also see this if there is a work instruction that controls how a piece of equipment is taken apart for cleaning – and the health and safety department introduces a safe system of work which controls how the piece of equipment should be safely taken apart. Both documents control the same process – so what should an operator do if there are conflicting instructions?

This kind of situation is dysfunctional because it allows for multiple, and possibly conflicting, management systems to operate concurrently. It makes it impossible to predict how a particular activity might be performed, and is preventative of change management or centralised control.

In quality assurance, there’s a trope where the quality manual sits gathering dust on a shelf in the office – while the people in the factory go about their business. This isn’t so much a remark on the extent to which quality processes are disseminated throughout a food business, it’s just dysfunctional management.

For there to be managerial control, the policies, procedures, and work instructions that make up the quality manual have to be fully integrated into operational processes. There’s no point trying to have factions of management with their own structure for interventions across different functions. Operations should be unified around business objectives, with a single system of management governing the component processes.

Operations should be fully aligned with the quality manual – not just for food safety and quality assurance, but because there’s no other way of sensibly managing a business.

Making The Quality Manual Accessible to All Staff

Documents that make up the quality manual should be subject to version control, and relevant staff should be trained against each new revision. With that acknowledged, the effective integration into operational processes depends on making the content of the quality manual available as a continual point of reference to the people who need it.

You want to create a situation where people preferentially look to the quality manual when they’re unsure of what to do – and making pertinent sections of the quality manual visually prominent in the area where an activity is being carried out really increases the likelihood that people will read them.

After people have been trained against procedures and work instructions, the relevance should not become ‘training record obtained’. The quality manual should be an active and present authority throughout the site’s operations – with the documented management structure acting as a practical authority over people’s actions.

Delivering ongoing access to the quality manual helps to form a relationship between employees and the management system. The quality manual must be present, and offer guidance, instruction, and clarity.

It’s not really feasible to expect anyone to memorise the content of every procedure they’ve ever read, so just being practical, it would be sensible to make the quality manual freely available as a reference.

Taking some extra steps to make the quality manual openly available throughout the workforce can have some hidden benefits for engagement, too. Some people are interested and curious – and if you give them access to the content of the quality manual, they’ll read it. Completely voluntarily, and without you having to tell them to. If you have those sorts of people working at your business, it won’t do your food safety and quality culture any harm at all if you let them pursue their curiosity about quality processes.

Advantages of Digital Systems

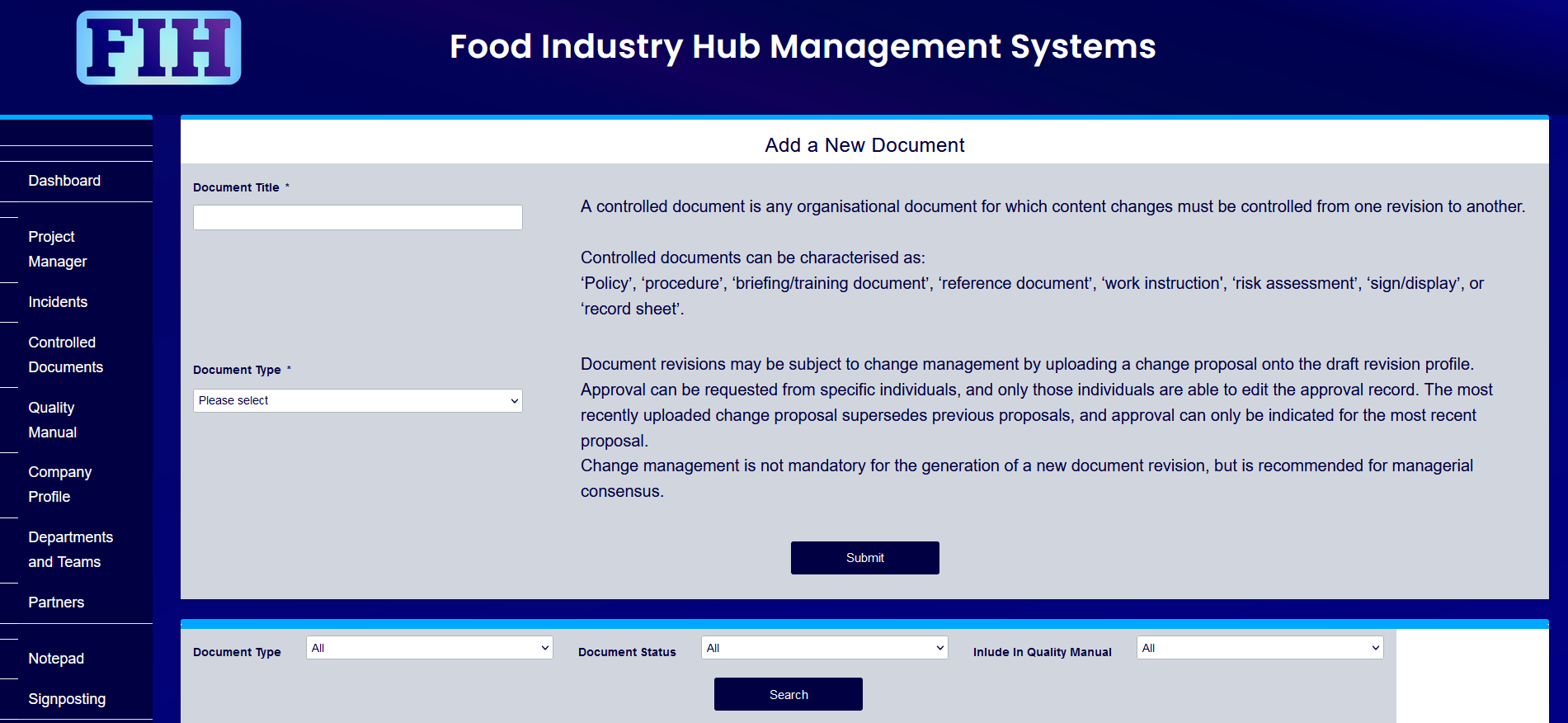

The systems offered by Food Industry Hub deliver a document control system as one feature among many included in a holistic package. The controlled documents module enables you to administrate documents and their revisions – along with incorporating change management. Updating a new revision has the instant effect of updating the quality manual with the new active revision and reason for change.

Individual users can be given access permission to add and edit controlled documents, or access the current/active revision of documents included in the quality manual, or both.

By making all documents centrally accessible (while restricting the users able to make changes), changes can be introduced at the click of a button – with all users provided with the new active revision instantaneously.

Similarly, providing all users with access to the current revision of every controlled document removes incentives for people to retain uncontrolled copies of documents – because they’ll have the assurance of knowing they’ll have access to the documents they need.

Accessibility, Legibility, and Overcoming Language Barriers

It’s essential to consider accessibility, legibility, and language barriers. These factors are critical in ensuring that the quality manual can be understood by everyone who uses it. This collection of documents should be available in different languages to represent the backgrounds represented throughout the workforce.

To enhance legibility, use clear fonts and colours that contrast well. The use of headings and subheadings can also help make the content more accessible. Ensure that the sentences are short and simple to increase readability.

Overcoming language barriers involves translating manuals into various languages spoken by employees. This process requires professional translation services to ensure accuracy and consistency in terminology. By addressing these issues during development, companies ensure that all stakeholders have access to information necessary for safe handling of food products while maintaining quality standards set out in their food safety plans.

Using pictures and diagrams can be incredibly helpful in supporting understanding. These visuals can help employees understand complex concepts and procedures that may be difficult to convey through text alone. For example, a diagram outlining the process of identifying and disposing of potentially contaminated food products can help employees quickly understand their responsibilities in preventing foodborne illnesses.

In addition to aiding understanding, pictures and diagrams can also serve as important reminders for employees. A picture of proper handwashing technique posted above a sink, or a diagram demonstrating how to properly store raw meat in a refrigerator, can serve as constant reminders for employees on how to maintain safety and quality standards.

Incorporating pictures and diagrams into your food safety and quality manual can greatly enhance employee understanding of important procedures while also serving as helpful reminders for ongoing compliance.

Designing Training Programs Around Your Quality Manual

Designing a training program around your quality manual is key to ensuring the successful implementation. The first step in this process is to review your quality manual and identify the key areas that require training. This could include topics such as HACCP principles, allergen management, sanitation practices, supplier control, or any other relevant information covered in your quality manual.

Once you have identified the key areas for training, you can begin developing a comprehensive training plan. This should include setting clear objectives for each training session, identifying suitable trainers or subject matter experts, and determining appropriate delivery methods (e.g., classroom-based instruction or online learning modules). It is also important to ensure that all employees receive the necessary training and that records are kept to demonstrate competence.

Finally, it is important to regularly review and update your training program as necessary to ensure that it remains effective and relevant. This could involve revisiting your quality manual periodically to identify any changes or updates required based on new regulations or industry best practices. By taking a proactive approach to designing your training program around your quality manual, you can help ensure ongoing compliance with food safety and quality standards while also enhancing employee knowledge and skills.

Outlining Record-Keeping Systems Within the Quality Manual

Effective record-keeping systems ensure that all necessary documentation is organised, easy to locate, and up to date.

It’s crucial to establish clear guidelines for how records should be created and maintained within the quality manual. Documenting details such as who is responsible for creating each record type, when they should be completed, and how long they must be retained will help ensure consistency across the organisation.

Outlining procedures for conducting internal audits of the record-keeping system can identify any gaps or deficiencies that need to be addressed. This allows companies to continually improve their processes and maintain compliance with regulatory requirements while ensuring product safety and quality are never compromised.

Evaluating Suitability: Is Your Quality Manual Fit for Purpose?

The quality manual outlines the policies, procedures, and requirements for producing safe and high-quality food products. However, it’s not enough to simply have a quality manual – it must also be fit for purpose. This means that the manual should be evaluated regularly to ensure that it continues to meet the needs of the organisation and align with industry best practices.

To evaluate whether your quality manual is fit for purpose, start by reviewing its content. Is it up to date? Are all relevant policies and procedures included? Have any changes in regulations or industry standards been incorporated? Consider whether the manual is easy to understand and use. Does it provide clear guidance for employees at all levels of the organisation?

Assess whether your quality manual is being effectively implemented. Do employees understand its contents? Are they following its procedures consistently? Are there any gaps or areas where additional training or resources may be needed? By regularly evaluating your quality manual’s suitability and making necessary updates, you can ensure that your organisation remains compliant with regulations while producing safe and high-quality products.

FAQ

what is a food safety and quality manual?

A food safety and quality manual is a comprehensive and structured document that outlines an organisation’s policies, procedures, work instructions, and expectations related to ensuring food safety and maintaining product quality. It serves as a central reference and guide for employees, management, and stakeholders to understand the processes, standards, and practices that are necessary to produce safe and high-quality food products.

Key components of a food safety and quality manual include:

Policies: Broad statements that express the organisation’s commitment to food safety and quality. These policies provide the guiding principles and values that the organisation adheres to in its operations.

Procedures: Detailed step-by-step instructions for performing specific tasks or activities. Procedures outline the processes that need to be followed to ensure consistent and safe production practices.

Work Instructions: Detailed instructions that guide employees through specific tasks or processes. Work instructions provide explicit guidance on how to perform tasks, often including diagrams, pictures, and specific requirements.

Reference Documents: Additional documents, standards, regulations, or guidelines that support the implementation of policies and procedures. These documents provide context and additional information for various processes.

Position Statements: Statements that outline the organisation’s stance on specific issues related to food safety and quality. These statements may cover topics like allergen management, hygiene practices, and more.

The food safety and quality manual serves several important purposes:

Standardisation: It helps standardise processes, procedures, and practices across the organisation, ensuring consistency and reducing errors.

Regulatory Compliance: The manual ensures that the organisation complies with industry standards, regulations, and best practices for food safety and quality.

Training: It provides a structured framework for training employees on the proper methods and practices for safe and high-quality food production.

Communication: The manual communicates the organisation’s commitment to food safety and quality to employees, stakeholders, and customers.

Internal Audits: It serves as a reference for internal audits to ensure that the organisation is following established procedures and meeting its quality and safety goals.

Continuous Improvement: The manual can be updated to incorporate new information, best practices, and lessons learned, promoting a culture of continuous improvement.

A well-designed and effectively implemented food safety and quality manual is a critical tool for organisations in the food industry. It helps create a culture of food safety and quality by providing clear guidance, promoting adherence to standards, and ensuring that all employees understand their roles in maintaining safe and high-quality food products.

What can happen if the quality manual is not properly integrated into operational processes?

If the quality manual is not properly integrated into operational processes, several negative consequences can arise that can impact the overall effectiveness of an organisation’s food safety and quality management system. Here are some potential outcomes of failing to integrate the quality manual effectively:

Inconsistent Practices: Without clear guidance from the quality manual, employees may adopt inconsistent practices and processes. This can lead to variations in how tasks are performed, which can compromise food safety and product quality.

Increased Risk: Failure to follow the procedures outlined in the quality manual can increase the risk of foodborne illnesses, product contamination, and quality defects. Inconsistencies in processes can result in unsafe products reaching consumers.

Regulatory Non-Compliance: Many regulatory standards require organisations to have documented procedures and practices for ensuring food safety and quality. If the quality manual is not integrated and followed, the organisation may fail to meet these regulatory requirements, leading to legal and regulatory issues.

Lack of Accountability: The quality manual outlines roles and responsibilities for maintaining food safety and quality standards. If these roles are not clearly defined and communicated, accountability may be lacking, and no one may take ownership of ensuring compliance.

Miscommunication: Ineffective integration can lead to miscommunication among employees about how tasks should be performed. This can result in misunderstandings, mistakes, and confusion, ultimately impacting the quality of products.

Resistance to Change: When employees are not accustomed to consulting the quality manual for guidance, they may resist changes or improvements that are introduced. This resistance can hinder the implementation of necessary updates or enhancements to processes.

Lack of Continuous Improvement: The quality manual is meant to evolve over time to incorporate lessons learned, best practices, and improvements. If it’s not integrated, opportunities for continuous improvement may be missed, and the organisation may become stagnant in its processes.

Loss of Employee Confidence: Employees may lose confidence in the organisation’s commitment to food safety and quality if the quality manual is not integrated. They may become disengaged and less likely to follow procedures.

Increased Costs: Inconsistencies and errors resulting from the lack of integration can lead to increased costs associated with rework, recalls, product waste, and potential legal actions.

Diminished Reputation: Failing to uphold food safety and quality standards can damage the organisation’s reputation. Consumers may lose trust in the brand, leading to decreased sales and market share.

To avoid these consequences, it’s crucial to ensure that the quality manual is not only well-designed but also effectively integrated into all operational processes. This involves training employees on how to use the manual, regularly reviewing and updating its content, and promoting a culture where the manual is seen as a valuable resource for maintaining food safety and quality standards.

In Summary

The foundation of a successful food management system lies in a robust food safety and quality manual. This manual comprises policies, procedures, work instructions, and expectations that ensure adherence to industry standards and regulations. It serves as a guide for both management and operational staff to maintain safe and high-quality food production. The manual encompasses tools for implementation, training, record-keeping, and reviews.

The quality manual is a documented system outlining an organisation’s quality management principles and policies, aimed at achieving safe and quality food. It guides processes, procedures, and responsibilities to maintain high-quality standards. It also serves as a reference for internal audits, to ensure regulatory compliance, and internal processes.

Implementing a strong food safety and quality manual is crucial for operational safety and high-quality food production. Proper documentation and regular audits for identifying improvements or non-compliance issues help maintain consistency and reduce risks associated with unsafe practices.

The manual compiles policies, procedures, work instructions, reference documents, and position statements, standardising processes and promoting consistency. This centralised system improves communication, alignment, and workflow efficiency across different departments, while ensuring compliance with food safety standards.

Policies provide direction, procedures detail task processes, and work instructions provide specific job guidance. These documents form a hierarchy within the quality manual, guiding actions and decisions. Alignment between operational actions and the quality manual’s documented requirements is essential for effective management.

To maximise effectiveness, the quality manual should be accessible to all staff, incorporating features like clear fonts, headings, subheadings, and visuals to overcome language barriers and enhance legibility. Making the manual readily available creates a relationship between employees and the management system, fostering engagement and understanding.

Designing training programs around the quality manual ensures effective implementation. Clear objectives, suitable trainers, and appropriate delivery methods should be identified. Regular review and updates are necessary to maintain compliance and enhance employee knowledge and skills.

A comprehensive record-keeping system outlined in the quality manual ensures organised, up-to-date documentation. Clear guidelines for record creation and maintenance, along with internal audits, help identify gaps and improve processes for sustained compliance.

Evaluating the quality manual’s fitness for purpose is crucial. Regular reviews ensure it remains up-to-date, aligned with regulations, easy to understand, and effectively implemented. By consistently evaluating and updating the quality manual, organisations can ensure regulatory compliance while producing safe and high-quality products.

Further Resources

Food Industry Hub serves the food industry with a range of digital resources for the benefit of both commercial food manufacturers and food industry professionals.

For food manufacturers, we offer integrated management systems that give every user a direct interface with your QMS.

For food industry professionals, we provide an extensive signposting service in addition to informational content we hope you’ll find useful as you face new professional challenges. We have very ambitious plans to expand the range of services offered, and currently present informational content on management, safety and quality, and professional success.