Introduction

So, you’ve noticed that your food manufacturing business could use a culture revamp. But how do you actually make that happen?

It’s not just about setting goals and hoping for the best. There’s a strategic process involved that requires commitment and finesse.

Let’s explore the key steps that will not only transform your organisational culture but also ensure long-term success in this competitive industry.

This post is part of a collection we’ve put together to explore the topic of food safety and quality culture, and you can explore the topic in more detail by browsing the related content.

Table of Contents

Key Takeaways

- Culture change is a long-term process that depends on continuous direction and reinforcement.

- There needs to be a clear understanding of the current culture in order to facilitate intended changes.

- It’s important to be clear about the exact nature of intended cultural developments – so that leadership, communication, and ongoing feedback can be aligned constructively.

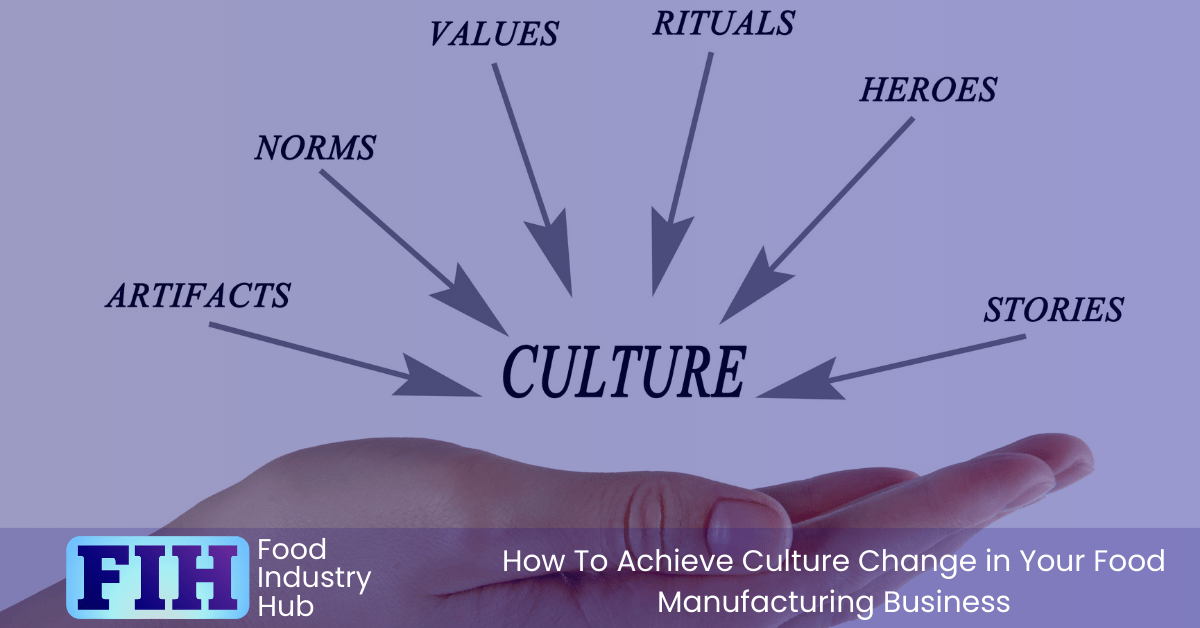

Assessing Current Organisational Culture

Assessing your current organisational culture begins with observing daily interactions and communication within the workplace. Pay attention to how employees collaborate, communicate, and problem-solve. Are discussions open and respectful, or do conflicts often arise?

Look at how decisions are made and whether employees feel empowered to contribute ideas. Take note of leadership styles and how managers interact with their teams. Are employees recognised for their efforts, or is there a lack of appreciation?

Assess how feedback is given and received across all levels of the organisation. By closely observing these aspects of your organisational culture, you can gain valuable insights into what’s working well and where improvements may be needed.

Setting Clear Objectives and Goals

To effectively drive culture change in food manufacturing, it’s you have to establish clear objectives and goals that align with the desired cultural shift. Setting specific and measurable targets provides a roadmap for the culture change initiative, and helps employees to understand what’s expected of them during the transformation process.

These objectives should be communicated transparently across all levels of the organisation to ensure everyone is on the same page. Clear goals help create a sense of direction and purpose, motivating employees to actively participate in the culture change being undertaken.

Sign-up for the Food Industry Hub Mail Service

We regularly produce new content for food industry professionals, and the Food Industry Hub Mail Service is the best way to stay up to date with the latest additions.

Signup today to be added to the Food Industry Hub mailing list.

Leadership Alignment and Buy-In

In order to achieve a successful culture change in food manufacturing, it’s crucial for leaders to align their vision and secure buy-in from all levels of the organisation.

Leadership alignment involves ensuring that all leaders are on the same page regarding the desired culture change and are committed to driving it forward. Buy-in from all levels of the organisation is essential to ensure that employees feel engaged and invested in the transformation process.

Leaders should communicate the reasons behind the change, listen to feedback, and involve employees in decision-making to increase their commitment. By obtaining leadership alignment and buy-in, the organisation can create a strong foundation for implementing lasting culture change in the food manufacturing business.

Communication Strategies and Channels

Choosing appropriate communication strategies and channels is helpful for values and ensuring buy-in from all levels of the organisation. Clear and consistent communication is key to fostering understanding and acceptance of new cultural norms.

Use a range of channels such as team meetings, email updates, intranet portals, and even social media platforms to reach employees at different levels and locations. Tailoring the message to resonate with each audience segment can enhance receptiveness.

Food safety and quality messaging can also be transmitted through artifacts such as posters, displays, and text on record sheets. This allows for a combination of personalised/interactive communication and consistent messaging – which means the most appropriate message can be delivered to the right people at the time and location that makes most sense. Permanently visible messaging from posters and displays can help to continually reinforce values that you with to promote as part of a culture shift.

Encourage open dialogue, feedback mechanisms, and two-way communication channels to promote transparency and address concerns promptly. By establishing effective communication strategies, you can create a supportive environment that facilitates successful culture change within your food manufacturing business.

Employee Engagement and Involvement

Engage your employees actively in the cultural transformation process to foster a sense of ownership and commitment towards the desired changes. People tend to be more receptive to a change that they contributed to than a change that was imposed upon them.

Encourage open communication channels for feedback and suggestions, making employees feel valued and heard. There should be an authentic sense of value attributed to employees’ points of view. This should be genuine and not performative – people can tell if they are being sincerely listened to and when they are being humoured.

Involve employees in decision-making processes related to the cultural shift, allowing them to contribute their ideas and perspectives.

Recognise and reward employees who actively participate in the change efforts, reinforcing a culture of engagement and involvement.

Create opportunities for team collaboration and bonding to strengthen relationships and build a cohesive culture.

Training and Development Programs

Implementing effective training and development programs is essential for cultivating a skilled and adaptable workforce. By providing ongoing opportunities for your employees to enhance their skills and knowledge, you empower them to perform at their best and adapt to changing industry demands.

Tailoring training programs to address specific areas of improvement can help employees excel in their roles and contribute to the overall success of the business. Encouraging a culture of continuous learning and development not only boosts employee morale but also enhances productivity and innovation within your organisation.

Values and cultural expectations are much like operational skills, in that they can be developed through training and educational processes. You might have a well-developed sense of the values, attitudes, beliefs, and behaviours that you expect employees to uphold, but you can’t just take it for granted that they will have the same understanding.

In the same way that a standard operating procedure can be used to convey to staff how to carry out a set of activities, you can document cultural expectations and train employees against those documented expectations. This can be accomplished through a staff handbook or a dedicated culture document.

Invest in comprehensive training initiatives that align with your business goals to ensure that your workforce remains competitive and capable of driving positive change in the food manufacturing sector.

Implementing Feedback Mechanisms

Establishing effective feedback loops is a very constructive way to encourage continuous improvement and communication within your food manufacturing team. Encouraging open channels for feedback allows employees to share insights, concerns, and suggestions for enhancing processes.

Enact regular feedback sessions where team members can provide input on challenges they face and propose solutions. Use anonymous surveys and confidential reporting systems to gather honest feedback and identify areas for improvement. Pay attention to the feedback received, acknowledge valid points, and take steps to address any issues raised promptly.

Recognising and Rewarding Progress

To build a culture of continuous improvement and motivation within your food manufacturing team, it’s essential to regularly acknowledge and reward progress made by individuals and the group as a whole. Recognising achievements, no matter how small, boosts morale and encourages employees to strive for excellence.

Celebrate milestones, whether it’s meeting production and quality targets, implementing innovative solutions, or demonstrating exceptional teamwork. Publicly acknowledging these accomplishments during team meetings, through emails, or even with small rewards can go a long way in reinforcing positive behaviours and encouraging a sense of pride within the team.

Monitoring Behaviours and Adjusting Strategies

After acknowledging progress and rewarding achievements, it’s essential to monitor behaviours and adjust strategies in order to maintain momentum and drive continued improvement within your food manufacturing team.

Keep a close eye on how employees are adapting to the changes in culture. Look for signs of resistance or areas where further support may be needed. Regular feedback sessions and open communication channels can help in identifying any issues early on.

If certain strategies aren’t yielding the expected results, be prepared to pivot and try new approaches. By staying vigilant and flexible, you can ensure that your team stays on track towards the desired culture change.

Sustaining Culture Change Efforts

Maintaining the momentum of culture development in your team requires consistent reinforcement of new behaviours and values. Keep communication channels open and transparent to address any concerns promptly.

Celebrate small wins along the way to boost morale and show progress. Encourage feedback from employees to ensure their voices are heard and valued in the change process.

Provide ongoing training and development opportunities to support employees in adapting to the new culture. Lead by example by embodying the desired behaviours and values yourself.

Remember that culture change is a journey, not a destination, so stay committed and persistent in your efforts. By sustaining these practices, you can embed the desired culture shift into the fabric of your food manufacturing business.

In Summary

Achieving culture change in a food manufacturing business requires assessing current culture, setting clear goals, gaining leadership buy-in, effective communication, engaging employees, implementing feedback mechanisms, recognising progress, monitoring behaviours, and sustaining efforts.

By following these steps and actively involving everyone in the process, you can successfully transform your organisation’s culture for the better. Remember, culture change is a continuous journey that requires dedication and commitment from all levels of the organisation.

From The Food Industry Hub Knowledge Centre

Featured pages from The Food Industry Hub Knowledge Centre:

Further Resources

Food Industry Hub serves the food industry with a range of digital resources for the benefit of both commercial food manufacturers and food industry professionals.

For food manufacturers, we offer integrated management systems that give every user a direct interface with your QMS.

For food industry professionals, we provide an extensive signposting service in addition to informational content we hope you’ll find useful as you face new professional challenges. We have very ambitious plans to expand the range of services offered, and currently present informational content on management, safety and quality, and professional success.