Introduction

Mastering a range of management concepts and approaches is essential for operational efficiency and sustained growth. When you consider the intricate web of factors influencing the food industry, from fluctuating consumer demands to evolving regulatory requirements, how can these methodologies be strategically leveraged to navigate the unique challenges faced by food manufacturers?

This post will introduce you to a collection of management concepts and approaches which you can apply to different circumstances and challenges for your food business.

Note: Some of the techniques listed here (e.g. Six Sigma) are routinely employed throughout the food industry. Others (e.g. Scrum) have traditionally been more closely associated with different applications, such as software development. The intention is to collate a constructive and innovative range of management tools which may be usefully applied in a food manufacturing setting.

Table of Contents

Key Takeaways

- SWOT analysis helps identify internal strengths/weaknesses and external opportunities/threats in food manufacturing.

- PEST analysis examines political, economic, social, and technological factors influencing food manufacturing operations.

- Porter’s Five Forces analysis aids in understanding competitive dynamics and industry attractiveness in food manufacturing.

- Six Sigma focuses on reducing defects and variations in processes to enhance efficiency and quality in food manufacturing.

- Lean Management streamlines operations, reduces waste, and improves productivity in food manufacturing.

Stay prepared at all times with the help of Food Industry Hub Management Systems, your ideal digital food safety solution.

SWOT Analysis

This strategic tool allows you to assess internal strengths and weaknesses along with external opportunities and threats, aiding in informed decision-making.

Definition

Analysing the strengths, weaknesses, opportunities, and threats within a food manufacturing business is crucial for developing a strategic plan – commonly known as a SWOT analysis.

Identifying your strengths allows you to leverage what sets your business apart from competitors. This could be skilled employees, efficient processes, or a strong brand reputation.

Recognising weaknesses enables you to address areas needing improvement, such as outdated equipment or limited distribution channels.

Opportunities in the food manufacturing industry could include growing consumer demand for organic products or expanding into new markets. By capitalising on these opportunities, you can drive business growth.

Threats like increasing competition or supply chain disruptions can pose risks to your operations. Understanding and mitigating these threats are essential for long-term success.

In essence, a SWOT analysis provides a comprehensive overview of your business’s internal and external factors, guiding strategic decision-making. By carefully evaluating these elements, you can develop effective strategies to maximise strengths, minimise weaknesses, seize opportunities, and mitigate threats in the competitive food manufacturing landscape.

Applications in Food Manufacturing

Utilising a SWOT analysis in food manufacturing allows you to strategically evaluate internal and external factors impacting your business’s performance. By conducting a SWOT analysis, you can identify your company’s Strengths, Weaknesses, Opportunities, and Threats.

Strengths are internal factors that give your food manufacturing business a competitive advantage, such as a strong brand reputation or efficient production processes.

Weaknesses are internal factors that may hinder your success, like outdated technology or high production costs.

Opportunities are external factors that your business could capitalise on, such as a growing demand for organic products or expanding into new markets.

Threats are external factors that could negatively impact your business, such as intense competition or changing consumer preferences.

Advantages

Assessing your food manufacturing business through a SWOT analysis can provide valuable insights into its competitive position and potential for growth. Conducting a SWOT analysis allows you to identify your Strengths, Weaknesses, Opportunities, and Threats, which can help in strategic planning and decision-making.

By analysing the internal strengths of your business such as a strong brand reputation or efficient production processes, you can leverage these advantages to stay ahead in the market. Understanding your weaknesses, like outdated technology or high production costs, enables you to address areas needing improvement.

Recognising external opportunities, such as expanding into new markets or introducing innovative products, can guide your business towards growth. Identifying potential threats like changing consumer preferences or increasing competition allows you to proactively mitigate risks.

Limitations

While SWOT analysis is a valuable tool for strategic planning, it does have its constraints.

One limitation is that it provides a snapshot in time and may not capture the dynamic nature of your industry. Factors such as market trends, evolving consumer preferences, and technological advancements can quickly change, rendering the analysis outdated.

Additionally, SWOT analysis tends to oversimplify complex issues by categorising them into four broad categories, potentially overlooking nuances that could be crucial for decision-making. Moreover, the subjective nature of SWOT analysis leaves room for bias, as individuals may interpret factors differently based on their perspectives.

PEST Analysis

Now, let’s explore the definition, applications in the industry, and advantages and limitations of PEST Analysis.

Definition

PEST stands for Political, Economic, Social, and Technological factors. These four categories help businesses assess the external environment in which they operate.

Political factors include government regulations, stability, and trade policies that can directly affect food manufacturing operations.

Economic factors cover aspects like inflation rates, economic growth, and exchange rates, which influence consumer spending patterns and the overall financial health of the industry.

Social factors delve into demographics, cultural trends, and consumer behaviours, providing insights into market demands and preferences within the food sector.

Technological factors encompass advancements in technology, automation, and innovation that can transform production processes and create competitive advantages.

Applications in Food Manufacturing

Exploring how PEST Analysis can be applied in food manufacturing provides valuable insights into the external factors impacting the industry.

In the political realm, regulations related to food safety, labelling, and environmental policies can significantly impact food manufacturing processes.

Economic factors such as inflation rates, labour costs, and consumer spending habits influence the profitability and competitiveness of food manufacturers.

Social factors like changing consumer preferences, health trends, and cultural shifts play a vital role in shaping product development and marketing strategies within the industry.

Technological advancements in food processing, packaging, and distribution have revolutionised the way food manufacturers operate, enhancing efficiency and quality.

Advantages

A PEST Analysis provides food manufacturing companies with a comprehensive understanding of the external factors influencing their operations. By analysing the Political, Economic, Social, and Technological aspects, companies can gain valuable insights into the macro environment in which they operate.

One advantage of using a PEST Analysis in food manufacturing is the ability to anticipate and adapt to regulatory changes. Understanding political factors helps companies navigate government policies related to food safety, labelling requirements, and environmental regulations. This insight enables proactive compliance and strategic decision-making.

Economically, a PEST Analysis assists in identifying market trends, consumer purchasing power, inflation rates, and exchange rates that could impact the industry. By staying informed on economic factors, food manufacturers can adjust pricing strategies, manage costs effectively, and capitalise on emerging opportunities.

Analysing social factors such as demographics, lifestyle changes, and cultural shifts allows companies to tailor their products to meet evolving consumer preferences.

Lastly, evaluating technological factors helps in embracing innovations that enhance production processes, quality control, and distribution channels.

This holistic view provided by a PEST Analysis equips food manufacturing companies to stay competitive and sustainable in a dynamic market landscape.

Limitations

While PEST Analysis is valuable for assessing external factors impacting a business, it has its drawbacks. One limitation lies in the potential oversimplification of complex issues. The analysis may not delve deep enough into the nuances of each factor, leading to a superficial understanding of the business environment.

Another limitation is the focus on external factors at the expense of internal considerations. PEST Analysis may overlook vital internal dynamics within a food manufacturing company, such as organisational culture or operational inefficiencies. Relying solely on external factors can hinder a comprehensive strategic planning process.

PEST Analysis is subject to changeable external factors. Market conditions, regulations, or societal trends can shift rapidly, rendering the analysis outdated or inaccurate. Continuous monitoring and updating of the analysis are essential to ensure its relevance in decision-making processes.

Recognising these limitations is crucial for using PEST Analysis effectively in the dynamic food manufacturing industry.

Sign-up for the Food Industry Hub Mail Service

We regularly produce new content for food industry professionals, and the Food Industry Hub Mail Service is the best way to stay up to date with the latest additions.

Signup today to be added to the Food Industry Hub mailing list.

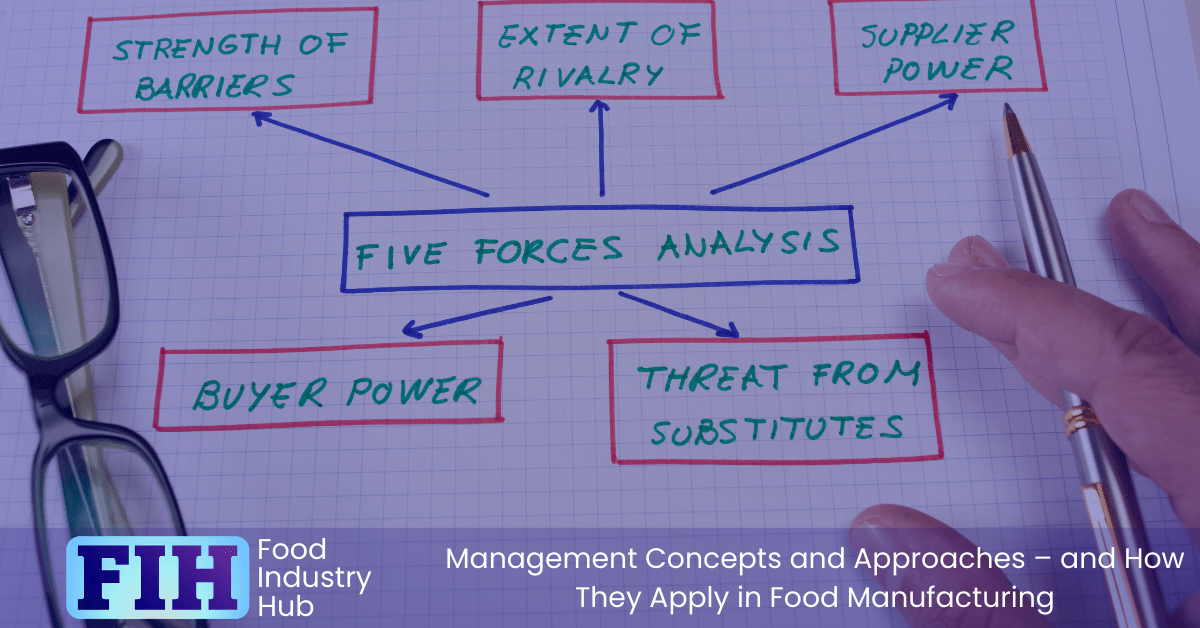

Porter’s Five Forces

Let’s explore Porter’s Five Forces, a strategic tool used to analyse the competitive environment of a business.

Porter’s Five Forces helps in understanding the forces influencing a company’s profitability and industry attractiveness.

Definition

This model, developed by Michael Porter, helps organisations assess the dynamics of their industry and make strategic decisions based on the competitive landscape.

The five forces include:

- The threat of new entrants, examining how easy it is for new competitors to enter the market and potentially disrupt existing business.

- The bargaining power of buyers, focusing on the ability of customers to negotiate prices and terms.

- The bargaining power of suppliers, assessing how much control suppliers have over input prices.

- The threat of substitutes, looking at the availability of alternative products that could attract customers away.

- The intensity of competitive rivalry, analysing the level of competition among existing firms in the industry.

Understanding these forces can help companies formulate strategies to navigate and succeed in their competitive environment.

Applications in Food Manufacturing

To apply Porter’s Five Forces model in the context of food manufacturing, consider how each force influences the competitive dynamics within the industry.

Threat of New Entrants: In food manufacturing, this force is influenced by factors like brand loyalty, economies of scale, and government regulations. Established brands with loyal customers and high barriers to entry due to large capital requirements or strict regulations can deter new entrants.

Bargaining Power of Suppliers: Suppliers of key ingredients or equipment can impact food manufacturers through pricing, quality, and availability. Strong supplier power can affect production costs and ultimately product pricing.

Bargaining Power of Buyers: In the food industry, buyers such as retailers or consumers can influence manufacturers through demand, price sensitivity, and product preferences. Understanding buyer behaviour is crucial for staying competitive.

Threat of Substitutes: Substitutes like alternative food products or dietary trends can impact consumer choices. Food manufacturers need to innovate and adapt to changing preferences to mitigate this threat.

Industry Rivalry: Intense competition in food manufacturing can lead to price wars, product differentiation, and marketing battles. Companies need to differentiate themselves to stand out in a crowded market.

Advantages

Analysing Porter’s Five Forces provides valuable insights into the competitive landscape of the food manufacturing industry. By examining the bargaining power of suppliers, you can understand how much control suppliers have over the pricing of raw materials. This awareness allows you to strategies effectively in negotiating favourable terms.

Assessing the threat of new entrants enables you to anticipate potential competition and innovate to maintain your market position.

Understanding the bargaining power of buyers helps you tailor your marketing and sales strategies to attract and retain customers. By recognising the competitive rivalry within the industry, you can identify areas for improvement and differentiation to stay ahead of competitors.

Evaluating the threat of substitute products empowers you to diversify your product offerings and enhance customer loyalty.

In essence, utilising Porter’s Five Forces equips you with a comprehensive understanding of the industry dynamics, enabling you to make informed decisions and gain a competitive edge in the food manufacturing sector.

Limitations

Assessing Porter’s Five Forces may present challenges in capturing the dynamic nature of the food manufacturing industry’s competitive landscape. While this framework can provide valuable insights into the competitive forces at play, it has limitations that you should consider.

One limitation lies in the static nature of the analysis. Porter’s Five Forces assesses industry competitiveness at a specific point in time, potentially overlooking the rapid changes that occur in the food manufacturing sector. This can lead to a lack of foresight into emerging trends or disruptive innovations that could significantly impact the industry landscape.

The model may oversimplify the complexity of relationships between the forces. In reality, these forces are interconnected and can influence each other in nuanced ways that Porter’s framework may not fully capture. This oversimplification could result in a superficial understanding of the industry dynamics, potentially leading to flawed strategic decisions.

While Porter’s Five Forces can provide a structured approach to analysing competitiveness, it’s sensible to supplement this framework with real-time data and a deeper understanding of the industry’s intricacies to make informed decisions in the dynamic food manufacturing landscape.

Six Sigma

Let’s kick off our exploration of Six Sigma in food manufacturing by looking at its definition, applications in the industry, as well as its advantages and limitations.

This methodology focuses on enhancing processes by minimising defects and variations, ultimately leading to improved efficiency and quality.

Understanding how Six Sigma can be effectively implemented, and its potential drawbacks presents a range of advantages for optimising operations in the food manufacturing sector.

Definition

Six Sigma is a data-driven methodology that focuses on improving processes by reducing defects or errors to a significant extent. The goal of Six Sigma is to minimise variation in processes to enhance efficiency and quality.

It’s structured around the DMAIC framework, which stands for Define, Measure, Analyse, Improve, and Control. This methodology relies heavily on statistical tools and techniques to identify root causes of defects and implement solutions to eliminate them.

Six Sigma depends on setting quantifiable goals and metrics to measure success. By defining specific targets and measuring performance against them, organisations can track their progress and ensure continuous improvement.

Six Sigma also places importance on the involvement of trained professionals known as Green Belts, Black Belts, and Master Black Belts who lead projects and drive change within the organisation.

Applications in Food Manufacturing

In food manufacturing, the implementation of Six Sigma methodologies has proven to be instrumental in enhancing operational efficiency and product quality. By focusing on minimising defects and variations in processes, Six Sigma helps food manufacturers achieve higher levels of consistency and reliability in their products.

Through the use of statistical analysis and data-driven decision-making, Six Sigma enables companies to identify areas for improvement, streamline operations, and reduce waste in the production process.

Six Sigma emphasises continuous improvement. By implementing a structured approach to problem-solving and process optimisation, companies can consistently meet customer expectations and regulatory requirements.

Six Sigma also enables organisations to better understand consumer needs and preferences, leading to the development of new products that align with market demands.

Advantages

Enhancing operational efficiency and product quality, Six Sigma methodologies in food manufacturing offer numerous advantages that drive continuous improvement and customer satisfaction. By implementing Six Sigma practices, you can significantly reduce defects in processes, leading to higher levels of consistency and reliability in your food products. This reduction in defects not only enhances the overall quality of your products but also minimises the likelihood of recalls – protecting your brand reputation.

Six Sigma enables you to streamline operations and eliminate waste, resulting in cost savings for your food manufacturing business. The methodology empowers your team to make data-driven decisions, fostering a culture of continuous improvement and innovation. Through the use of statistical tools and analysis, you can identify root causes of issues and implement targeted solutions to enhance efficiency throughout your production processes.

Limitations

By focusing solely on statistical analysis and data-driven solutions, Six Sigma may overlook the importance of qualitative factors and human judgment in food manufacturing processes. While Six Sigma excels at improving efficiency, reducing defects, and optimising processes through its rigorous methodology, it can sometimes lead to a tunnel vision approach.

In food manufacturing, where variables such as taste, texture, and overall consumer experience are critical, relying solely on numbers can miss the mark.

Another limitation of Six Sigma in food manufacturing is the potential disconnect between the statistical goals and the overall strategic objectives of the company. Focusing too heavily on meeting statistical targets may divert attention from broader business goals, such as innovation, market responsiveness, and customer satisfaction.

The strict adherence to predefined processes and metrics in Six Sigma may stifle creativity and flexibility in adapting to changing market demands or unexpected challenges. In a dynamic industry like food manufacturing, where trends and consumer preferences evolve rapidly, the rigid structure of Six Sigma may hinder the agility required to stay competitive.

Lean Management

Now let’s talk about Lean Management in food manufacturing.

We’ll explore its definition, applications in the industry, along with the advantages and limitations it brings.

Understanding these key points will help you grasp the impact of Lean Management on food manufacturing processes.

Definition

Lean Management is a systematic approach to identifying and eliminating waste in processes to maximise value for customers. By focusing on efficiency and continuous improvement, Lean Management aims to streamline operations and enhance overall productivity. The core principle of Lean Management is the elimination of activities that don’t add value to the final product or service.

One key aspect of Lean Management is the concept of ‘muda,’ which refers to any activity that consumes resources without creating value. Identifying and eliminating muda is essential in Lean Management to optimise processes and minimise unnecessary costs.

Lean Management also emphasises the importance of empowering employees at all levels to actively participate in process improvement initiatives. In essence, Lean Management is about creating a culture of continuous improvement, where every member of the organisation is encouraged to seek out inefficiencies and propose solutions.

Applications in Food Manufacturing

Implementing Lean Management principles in food manufacturing involves identifying and eliminating waste to optimise processes and enhance efficiency. By focusing on continuous improvement and maximising value while minimising resources, Lean Management aims to streamline operations and deliver high-quality products consistently.

In food manufacturing, this approach can lead to reduced lead times, lower production costs, and improved overall quality.

One key aspect of Lean Management in food manufacturing is the concept of Just-in-Time production, where inventory levels are minimised to only what’s necessary for immediate production needs. This helps in reducing storage costs, minimising waste from expired products, and enhancing the overall flow of operations.

Implementing visual management techniques, such as Kanban boards, can help teams visualise workflows, identify bottlenecks, and address issues promptly.

Advantages

To maximise efficiency and streamline operations in food manufacturing, embracing Lean Management principles offers numerous advantages. By implementing Lean methodologies, you can significantly reduce lead times, eliminate waste, and enhance overall productivity. Lean Management enables you to identify and address inefficiencies in your processes, leading to cost savings and improved quality control. Through the continuous improvement mindset of Lean, you empower your team to identify bottlenecks and implement solutions swiftly, fostering a culture of innovation and collaboration.

Another advantage of Lean Management in food manufacturing is the emphasis on customer value. By focusing on what the customer truly values, you can tailor your production processes to meet those needs efficiently, resulting in higher customer satisfaction and loyalty.

Lean principles also promote a safer work environment by reducing hazards and standardising procedures, leading to fewer accidents and improved employee well-being.

Limitations

While Lean Management offers numerous benefits like waste reduction and improved efficiency, it’s essential to acknowledge its limitations to effectively navigate the implementation phase.

One significant limitation of Lean Management in food manufacturing is the resistance to change from employees. Implementing Lean practices often requires a shift in mindset and operations, which can be met with scepticism and pushback from workers accustomed to traditional methods. Overcoming this resistance necessitates clear communication, training, and involving employees in the process to ensure buy-in and cooperation.

Another limitation is the potential for overemphasis on cost-cutting at the expense of quality. In the pursuit of efficiency, there’s a risk of compromising product quality or food safety standards. Balancing cost reduction efforts with maintaining high-quality standards is crucial to prevent negative impacts on customer satisfaction and brand reputation.

Agile Management

Let’s begin our discussion on Agile Management in the context of food manufacturing.

We’ll explore its definition, applications in the industry, as well as its advantages and limitations.

Understanding these key points will give you a comprehensive view of how Agile Management can impact food manufacturing processes.

Definition

Understanding Agile Management involves embracing a flexible and iterative approach to project management. In Agile, projects are broken down into smaller increments known as sprints, allowing for continuous feedback and adaptation throughout the development process. This methodology values individuals and interactions over processes and tools, promoting collaboration and communication within cross-functional teams.

Agile Management prioritises responding to change over following a rigid plan. It encourages quick decision-making, empowering teams to make necessary adjustments based on evolving requirements. By promoting adaptability and transparency, Agile fosters a culture of continuous improvement and customer satisfaction.

An essential aspect of Agile is the concept of self-organising teams. These teams are given the autonomy to determine how they’ll accomplish their goals, fostering creativity and ownership among team members. This decentralised approach empowers individuals to take responsibility for their work and encourages innovation.

Applications in Food Manufacturing

Agile Management can be adopted by food manufacturing companies to enhance flexibility and adaptability in their production processes. In the fast-paced and ever-changing food industry, the ability to quickly respond to market demands and consumer preferences is crucial. Agile Management principles, borrowed from software development, are proving to be highly beneficial in the food manufacturing sector.

By implementing Agile Management practices, food companies can streamline their operations, reduce lead times, and improve overall efficiency. This approach allows for greater collaboration between different departments, fostering innovation and continuous improvement. Cross-functional teams work together to tackle challenges and capitalise on opportunities, leading to faster decision-making and implementation.

Through Agile Management, food manufacturers can better handle unforeseen events such as supply chain disruptions or changing regulations. The iterative nature of Agile allows companies to test and adapt their processes in real-time, ensuring they stay competitive and meet consumer demands effectively.

Advantages

Implementing Agile Management practices in food manufacturing brings numerous benefits to companies seeking to improve their flexibility and adaptability in today’s fast-paced industry. By adopting Agile methodologies, you can respond more quickly to changing consumer demands and market trends.

Agile Management fosters better collaboration among cross-functional teams, allowing for improved communication and problem-solving. This approach promotes a culture of continuous improvement, where feedback loops are shorter, enabling you to make timely adjustments and innovations.

Agile Management also enhances efficiency by breaking down complex processes into manageable tasks with shorter development cycles. This iterative approach helps in identifying and rectifying issues early on, reducing the likelihood of costly errors.

Agile practices empower employees by promoting autonomy and decision-making at lower levels, leading to higher engagement and job satisfaction. Ultimately, Agile Management in food manufacturing can result in improved product quality, faster time-to-market for new products, and a competitive edge in the dynamic industry landscape.

Limitations

While Agile Management has numerous benefits, it also comes with its own set of challenges and limitations in the context of food manufacturing. One significant limitation is the potential resistance from employees who may find it difficult to adapt to the fast-paced and constantly changing nature of Agile methodologies. This resistance can hinder the successful implementation of Agile practices in food manufacturing.

The emphasis on quick decision-making in Agile Management may lead to overlooking critical quality control measures in food production. Rushing through processes to meet short-term goals could compromise the overall quality and safety of food products, ultimately risking consumer health and trust in the brand.

The iterative nature of Agile Management may not align well with the strict regulations and compliance requirements in the food industry. Adapting to frequent changes and iterations could introduce complexities in maintaining regulatory standards, potentially leading to non-compliance issues.

OKR (Objectives and Key Results)

Let’s start by defining OKR (Objectives and Key Results) and how it’s applied in food manufacturing.

We’ll explore its advantages and consider its limitations within the context of managing objectives and achieving key results in the industry.

Understanding these points will provide valuable insights into implementing OKR effectively in food manufacturing.

Definition

OKR is a goal-setting framework that helps organisations define and track objectives and their outcomes. Objectives are the goals a company wants to achieve, providing direction and purpose, while key results are measurable outcomes that indicate progress towards those objectives.

The key results are specific, measurable, achievable, relevant, and time-bound (SMART), enabling teams to focus on what truly matters for success.

In the context of food manufacturing, OKRs can be used to improve various aspects such as product quality, operational efficiency, and customer satisfaction. By setting clear objectives like reducing production waste by a certain percentage or increasing on-time delivery rates, food manufacturing companies can align their teams towards common goals and measure their progress effectively.

This framework encourages transparency, accountability, and continuous improvement within the organisation, ultimately driving better results and performance in the competitive food industry.

Applications in Food Manufacturing

Implementing OKR (Objectives and Key Results) in food manufacturing can significantly enhance goal alignment and performance tracking within the organisation. By setting clear objectives and measurable key results, you can ensure that everyone in the company is working towards the same goals.

In food manufacturing, this is crucial for ensuring product quality, safety standards, and operational efficiency. OKRs can help align different departments, such as production, quality control, and supply chain management, towards overarching objectives like reducing waste, improving delivery times, or launching new product lines.

With OKRs, you can track progress transparently, allowing for real-time adjustments and interventions when needed. This level of visibility can lead to increased accountability and motivation among teams.

OKRs can facilitate communication and collaboration across various levels of the organisation, breaking down silos and fostering a culture of continuous improvement. By implementing OKRs in food manufacturing, you can drive performance, innovation, and ultimately, achieve strategic objectives efficiently.

Advantages

Incorporating OKRs (Objectives and Key Results) in food manufacturing operations can yield several advantages for driving performance and achieving strategic goals efficiently. By implementing OKRs, you can enhance alignment within your teams, ensuring that everyone is working towards common objectives. This alignment fosters collaboration and boosts overall productivity.

OKRs provide a clear framework for setting ambitious yet achievable goals, allowing you to measure progress effectively.

Another advantage of utilising OKRs in food manufacturing is the increased transparency they bring to the organisation. By defining specific key results that indicate progress towards objectives, OKRs enable teams to track performance transparently. This transparency promotes accountability and helps in identifying any gaps that need to be addressed promptly.

OKRs encourage continuous improvement by emphasising learning and adaptation. Through regular check-ins and updates on key results, teams can make data-driven decisions and pivot strategies as needed, fostering agility in a dynamic industry like food manufacturing.

Limitations

One key limitation is the potential for OKRs to create a tunnel vision focus on short-term objectives, potentially overlooking broader strategic goals. In the dynamic environment of the food industry, this narrow focus may hinder long-term growth and adaptability to changes in consumer preferences or market trends.

The rigid structure of OKRs, with predefined key results, may not always allow for the flexibility needed in the ever-evolving landscape of food manufacturing. This lack of adaptability could lead to missed opportunities or the inability to quickly pivot strategies in response to unforeseen circumstances.

If OKRs aren’t aligned with the overall mission and values of the food manufacturing company, they may fail to motivate employees or foster a sense of purpose in their work. Without this alignment, OKRs may become mere checkboxes to tick off rather than driving meaningful progress towards the organisation’s overarching goals.

It’s essential for food manufacturing companies to carefully evaluate these limitations to ensure that the implementation of OKRs is done thoughtfully and effectively.

Scrum

Let’s start by defining Scrum in the context of food manufacturing and exploring its applications within the industry.

We’ll discover the advantages Scrum can offer in terms of enhancing efficiency, collaboration, and adaptability in your production processes.

However, it’s also crucial to be aware of the limitations that may arise when implementing Scrum in a food manufacturing setting.

Definition

Scrum is a framework that promotes collaboration, iterative progress, and the ability to respond to change quickly. In the world of food manufacturing, where efficiency and adaptability are crucial, Scrum offers a structured approach to managing projects and teams.

At its core, Scrum involves breaking down a project into smaller, manageable tasks called sprints. These sprints typically last 2-4 weeks and result in a potentially shippable product increment. By focusing on delivering working products frequently, Scrum enables food manufacturing teams to gather feedback early and make adjustments as needed.

Key roles in Scrum include the Product Owner, responsible for maximising the value of the product, the Scrum Master, who ensures the team follows Scrum practices, and the Development Team, responsible for delivering the product increment. Together, these roles collaborate closely to ensure that the project stays on track and meets the needs of the food manufacturing business.

Applications in Food Manufacturing

Implementing Scrum methodology in food manufacturing operations revolutionises project management practices. By adopting Scrum, you can enhance collaboration among cross-functional teams, improve flexibility in responding to changes, and increase the overall efficiency of your projects.

Scrum’s iterative approach allows for quick adjustments to be made based on customer feedback or market demands. Scrum helps you prioritise tasks effectively, ensuring that critical aspects of production are addressed promptly.

Daily stand-up meetings promote communication and transparency, keeping everyone aligned towards common goals. The use of Scrum boards visually displays tasks, progress, and bottlenecks, aiding in better decision-making and resource allocation.

Regular reviews and retrospective meetings allow for continuous improvement and learning from past experiences. In food manufacturing, where time-to-market is crucial, Scrum enables you to deliver high-quality products efficiently while maintaining a competitive edge in the industry.

Embracing Scrum methodology empowers your teams to adapt swiftly to evolving circumstances, ultimately leading to enhanced productivity and customer satisfaction.

Advantages

Scrum methodology in food manufacturing offers numerous benefits that significantly enhance project management practices. By implementing Scrum, you can enjoy increased flexibility in adapting to changing market demands. This iterative approach allows for frequent inspection and adaptation, enabling you to respond swiftly to shifts in consumer preferences or unexpected challenges.

Collaboration is a key advantage of Scrum in food manufacturing. The framework promotes cross-functional teamwork, fostering a culture of shared responsibility and collective problem-solving. This collaborative environment enhances communication, leading to improved decision-making and ultimately better outcomes for your projects.

Scrum promotes transparency throughout the project lifecycle. With regular meetings such as daily stand-ups and sprint reviews, everyone involved has visibility into the progress being made and any impediments that may arise. This transparency helps in identifying issues early on and addressing them promptly, reducing the risk of delays or costly errors.

Limitations

Despite the benefits of Scrum methodology in food manufacturing, there are certain limitations that can impact its effectiveness in project management practices. One key limitation is the need for a high level of collaboration and communication among team members. If there are communication breakdowns or team members who aren’t fully engaged, the Scrum process can be hindered.

Scrum may not be suitable for all types of projects. Projects that require a strict and detailed plan from the beginning may find the iterative and adaptive nature of Scrum challenging.

Another limitation is the potential for scope creep. Without clear boundaries and a strong product owner, there’s a risk that the project scope may expand beyond what was initially intended, leading to delays and increased costs.

In some cases, the time constraints of Scrum sprints may not align with the complex requirements of certain food manufacturing projects, making it difficult to deliver a fully acceptable product within the short time frames. It’s essential to carefully consider these limitations and assess whether Scrum is the most suitable methodology for a particular project in the food manufacturing industry.

SMART Goals

Let’s explore the definition, applications, advantages, and limitations of setting SMART Goals within this industry.

This will provide you with a clear framework to effectively implement and measure the success of your goals in food manufacturing settings.

Definition

When setting goals in food manufacturing, it’s essential to define them using the SMART criteria for increased effectiveness and clarity. SMART stands for:

- Specific goals are clear and well-defined, leaving no room for ambiguity.

- Measurable goals provide a way to track progress and determine when the goal has been achieved.

- Achievable goals are realistic considering available resources and constraints.

- Relevant goals align with the overall objectives of the organisation, contributing to its success.

- Time-bound goals have a defined deadline, creating a sense of urgency and accountability.

Applications in Food Manufacturing

Implementing SMART goals in food manufacturing is crucial for enhancing operational efficiency and driving performance improvements. Setting Specific goals helps in providing clear direction to your team. For instance, a Specific goal could be reducing production waste by 15% in the next quarter.

Measurable goals allow you to track progress effectively. You can measure the waste reduction through regular audits and data analysis.

Achievable goals ensure that your targets are realistic and attainable with the available resources. For example, setting a goal of reducing production waste by 50% in a month mightn’t be feasible.

Relevant goals align with the overall objectives of the company. If the primary focus is on sustainability, setting goals related to reducing waste align with the broader mission.

Time-bound goals provide a clear deadline for achieving targets, fostering a sense of urgency and accountability. By setting SMART goals in food manufacturing, you can drive success and continuous improvement in your operations.

Advantages

Embracing SMART goals in food manufacturing can significantly enhance your operational efficiency and drive performance improvements. By setting Specific, Measurable, Achievable, Relevant, and Time-bound goals, you provide your team with clear direction and targets to work towards. This clarity helps align everyone’s efforts, ensuring that resources are utilised effectively.

SMART goals also promote accountability within your organisation. When objectives are well-defined, individuals understand their responsibilities in achieving them. This accountability fosters a culture of ownership and commitment, motivating employees to strive for success.

Implementing SMART goals can lead to increased productivity and innovation. When employees have specific targets to meet, they’re more likely to focus on finding creative solutions to overcome challenges and achieve results. This focus on innovation can drive continuous improvement throughout your food manufacturing processes.

Limitations

Using SMART goals in food manufacturing may present challenges that can hinder your organisational progress and effectiveness. One limitation you might encounter is the rigidity that comes with setting specific, measurable targets. While these goals can provide clarity, they may also restrict flexibility in responding to unforeseen circumstances or market changes. Additionally, the process of defining achievable goals that are both realistic and time-bound can be complex in the dynamic environment of food manufacturing.

Another limitation is the potential for overlooking the interconnected nature of different functions within a food manufacturing organisation. Focusing solely on individual SMART goals without considering how they align with broader company objectives can lead to siloed thinking and suboptimal overall performance.

The emphasis on measurable outcomes may inadvertently discourage risk-taking and innovation, as employees may prioritise meeting predetermined targets over exploring new ideas.

To mitigate these limitations, it’s essential to strike a balance between setting SMART goals and fostering a culture that values adaptability, collaboration, and creativity in food manufacturing processes. By recognising these constraints and actively addressing them, you can enhance the effectiveness of SMART goals within your organisation.

Change Management

Let’s delve into Change Management in the context of food manufacturing.

This involves understanding its definition and applications in the industry.

We’ll also discuss its advantages and limitations.

Definition

Change management involves strategically planning and implementing adjustments within an organisation to facilitate smooth transitions and achieve desired outcomes. It’s a structured approach that helps individuals, teams, and the organisation as a whole adapt to change effectively.

The primary goal of change management is to minimise resistance and maximise engagement during the transition process.

By defining change management, you can understand its importance in driving successful organisational transformations. It encompasses various aspects such as communication, training, and stakeholder involvement to ensure that changes are well-received and integrated seamlessly into the existing framework.

Effective change management requires clear objectives, strong leadership, and open communication channels. It’s essential to have a well-defined strategy that outlines the reasons for change, the expected outcomes, and the steps needed to achieve them.

Ultimately, change management is about fostering a culture that embraces change as a constant and necessary part of organisational growth and development.

Applications in Food Manufacturing

Implementing effective change management strategies in food manufacturing involves aligning operational processes with organisational goals to enhance adaptability and drive sustainable growth. Change management in this context requires a systematic approach to implementing changes in production processes, technology adoption, and workforce management while minimising disruptions to daily operations. By effectively managing change, food manufacturers can respond swiftly to market trends, consumer demands, and regulatory requirements.

Key elements of successful change management in food manufacturing include: – Clear communication of the reasons for change – Involvement of employees at all levels – Providing adequate training and support to facilitate the transition.

It’s crucial to create a culture that embraces change as a continuous improvement opportunity rather than a disruptive force. Moreover, leveraging data analytics and technology can help in identifying areas for improvement and monitoring the impact of changes on key performance indicators.

Advantages

By consistently applying effective change management strategies, food manufacturers can enhance operational efficiency and drive sustainable growth in their production processes.

Embracing change within the food manufacturing industry offers several key advantages. Firstly, it allows companies to adapt to evolving consumer preferences and market trends swiftly. This agility enables businesses to stay ahead of the competition and meet customer demands effectively.

Implementing changes thoughtfully can lead to cost savings by streamlining processes, reducing waste, and enhancing productivity.

Another significant advantage of prioritising change management is the boost in employee engagement and morale. Involving employees in the change process fosters a sense of ownership and empowerment, leading to increased job satisfaction and motivation.

Effective change management can improve overall organisational resilience by creating a culture that’s open to innovation and continuous improvement.

Ultimately, by proactively managing change, food manufacturers can position themselves for long-term success and sustainability in a dynamic and competitive industry.

Limitations

While navigating change in food manufacturing, it’s you have to acknowledge the inherent challenges and limitations of implementing effective change management strategies. One significant limitation is resistance from employees who may be hesitant to embrace new processes or technologies. Overcoming this resistance requires clear communication, employee involvement, and a supportive organisational culture.

Another limitation is the potential disruption to daily operations during the change implementation phase. This disruption can lead to decreased productivity and increased costs if not managed effectively. To mitigate this, careful planning, realistic timelines, and adequate resources are essential.

Additionally, a lack of leadership support and commitment can hinder the success of change management efforts. Without strong leadership advocating for and driving the change, employees may not take the initiative seriously or fully commit to the new ways of working.

Decision Tree Analysis

You’re about to explore Decision Tree Analysis in the context of food manufacturing.

This analysis method involves mapping out decisions and their potential outcomes in a tree-like structure.

Definition

Understanding decision tree analysis is helpful in defining management concepts and approaches within the context of food manufacturing. Decision tree analysis is a visual representation of possible decision outcomes and their consequences. It involves breaking down complex decisions into a series of manageable choices, leading to an organised decision-making process.

In food manufacturing, decision tree analysis helps in evaluating various factors impacting production efficiency, product quality, and overall business success. By using decision trees, food manufacturing managers can assess different scenarios, such as ingredient sourcing options, production methods, or distribution strategies. This analysis aids in identifying potential risks, opportunities, and optimal paths to achieve desired outcomes.

It provides a structured framework for considering uncertainties and making informed decisions based on available data. Decision tree analysis enables managers to weigh the costs and benefits associated with each decision branch, facilitating a systematic approach to problem-solving.

Ultimately, mastering decision tree analysis in food manufacturing enhances managerial decision-making capabilities, leading to more effective and strategic operational outcomes.

Applications in Food Manufacturing

In food manufacturing, applying decision tree analysis allows managers to strategically evaluate various operational scenarios for improved decision-making. By using decision trees, you can visually map out different choices and their potential outcomes, helping you make informed decisions based on probabilities and potential risks.

For instance, when deciding whether to invest in new equipment for a production line, a decision tree can outline the possible outcomes such as increased efficiency, maintenance costs, and potential downtime, aiding in weighing the benefits against the risks.

Decision tree analysis can assist in optimising processes such as inventory management. By creating decision nodes that represent choices like reorder quantities (thing MOQs – minimum order quantities) or supplier selection, you can analyse the potential consequences of each decision branch and select the most cost-effective and efficient option.

This method not only enhances decision-making but also promotes a structured approach to problem-solving in complex food manufacturing environments.

Advantages

When utilising decision tree analysis in food manufacturing, managers can efficiently assess various operational scenarios to enhance decision-making processes. One advantage of decision tree analysis is its ability to visually represent complex decisions, making it easier for managers to understand the potential outcomes of different choices.

This visual representation can aid in identifying the best course of action based on probabilities and potential risks.

Another advantage is that decision tree analysis allows for the incorporation of both quantitative and qualitative factors into the decision-making process. This means that managers can consider not only financial implications but also factors such as customer preferences, market trends, and regulatory requirements when making decisions.

Decision tree analysis promotes a systematic approach to decision-making, helping managers to break down complex problems into smaller, more manageable components. By evaluating the different branches of the decision tree, managers can weigh the pros and cons of each option and select the one that aligns best with their strategic goals.

Limitations

Despite its advantages, decision tree analysis in food manufacturing also comes with limitations that can impact its effectiveness in certain situations. One significant limitation is the complexity that arises when dealing with a large number of decision nodes and branches. As the decision tree grows in size and intricacy, it becomes more challenging to interpret and may lead to errors in analysis.

Another limitation is the assumption of independence between variables in the decision-making process. In reality, variables in food manufacturing processes may be interdependent, leading to inaccuracies in the decision tree model. This can result in suboptimal decisions being made based on false assumptions of independence.

Decision tree analysis may struggle with continuous variables, as it’s inherently more suitable for categorical variables. When dealing with continuous data, discretisation is required, which can introduce bias and reduce the accuracy of the analysis.

Root Cause Analysis

Let’s start exploring Root Cause Analysis, a powerful tool in understanding the underlying reasons for issues in food manufacturing processes.

This method allows you to pinpoint the root causes of problems rather than just addressing the symptoms, leading to more effective solutions.

Definition

Exploring the concept of root cause analysis is essential in understanding the underlying factors contributing to issues within food manufacturing processes. Root cause analysis is a systematic method used to identify the primary cause of a problem or an event. It involves delving beyond the surface-level symptoms to uncover the fundamental reasons behind issues that arise in food manufacturing.

By conducting a root cause analysis, you can pinpoint the exact source of a problem, rather than just addressing its immediate effects. This approach aims to prevent the recurrence of similar issues by addressing their foundational causes.

In food manufacturing, root cause analysis plays a crucial role in enhancing quality control, improving processes, and ensuring product safety. It allows companies to proactively identify and rectify issues that could potentially impact the quality or safety of their products.

Applications in Food Manufacturing

Using root cause analysis in food manufacturing enables you to pinpoint underlying issues and implement targeted solutions for enhanced quality control and product safety. By delving deep into the root causes of problems rather than just addressing symptoms, you can identify recurring issues and prevent them from affecting product quality.

This approach involves investigating factors such as equipment malfunctions, human error, and process deviations that may lead to contamination or compromised product integrity.

In the context of food manufacturing, root cause analysis plays a crucial role in maintaining compliance with regulatory standards and meeting consumer expectations for safe and high-quality products.

For instance, if there’s a sudden rise in product defects or instances of contamination, conducting a thorough root cause analysis can help you identify the specific steps in the production process that leads to issues arising.

This targeted approach allows you to make necessary adjustments promptly, ensuring that product safety and quality standards are consistently met.

Advantages

Investigating the root causes of issues in food manufacturing offers distinct advantages for enhancing product safety and quality control. By drilling deep into the underlying reasons behind problems, you can prevent them from recurring and improve overall production processes.

Identifying root causes enables you to implement targeted solutions that address the core issues rather than just treating symptoms. This approach not only saves time and resources but also leads to long-term efficiency gains.

Root cause analysis promotes a culture of continuous improvement within your organisation. It encourages proactive problem-solving and fosters a mindset focused on preventing issues before they escalate. By consistently analysing and addressing root causes, you can optimise operations, minimise risks, and uphold high standards of quality and safety.

Understanding the root causes of issues empowers you to make informed decisions based on data and evidence. This data-driven approach enhances transparency and accountability, helping you build trust with stakeholders and consumers.

Ultimately, by harnessing the advantages of root cause analysis, you can drive sustainable improvements that elevate your food manufacturing processes to new heights.

Limitations

While root cause analysis is a valuable tool for identifying the underlying reasons for issues, it does have its constraints.

One limitation is the complexity of food manufacturing processes, which can make it difficult to pinpoint a single root cause for a problem. Additionally, the time and resources required for a thorough root cause analysis can be extensive, especially in a fast-paced industry like food manufacturing where quick solutions are often needed.

Another limitation is the potential for bias in the analysis process, as preconceived notions or assumptions can impact the identification of true root causes. The effectiveness of root cause analysis heavily relies on the quality of data collected, and inaccuracies or missing information can lead to incorrect conclusions.

Implementing solutions based on root cause analysis findings may not always guarantee long-term success, as unforeseen factors or changes in the manufacturing environment can impact the effectiveness of the chosen solution. Recognising these limitations is essential for utilising root cause analysis effectively in food manufacturing.

Business Process Reengineering (BPR)

You should first understand the core ideas behind Business Process Reengineering (BPR) in food manufacturing.

It involves rethinking and redesigning processes to achieve significant improvements in efficiency and effectiveness.

Definition

Business Process Reengineering (BPR) involves the fundamental rethinking and redesign of processes within a food manufacturing company to improve operational efficiency and effectiveness. BPR aims to streamline workflows, eliminate redundancies, and enhance overall performance by focusing on the core objectives of the organisation.

This approach goes beyond making incremental changes and instead advocates for a radical transformation of how tasks are carried out. By reevaluating existing procedures from a fresh perspective, BPR enables companies to identify bottlenecks, inefficiencies, and outdated practices that hinder growth and success.

The essence of BPR lies in challenging the status quo and embracing innovative solutions to drive continuous improvement. Through BPR, companies can achieve substantial cost reductions, faster turnaround times, higher quality outputs, and increased customer satisfaction.

This proactive methodology empowers organisations to adapt to changing market demands and stay ahead of the competition.

Applications in Food Manufacturing

By implementing BPR in food manufacturing, you can streamline operations, eliminate redundant tasks, and enhance overall productivity. BPR involves rethinking and redesigning processes from scratch, focusing on achieving significant improvements in speed, quality, and cost-effectiveness.

In food manufacturing, this approach can lead to faster production cycles, reduced waste, and improved resource utilisation.

Through BPR, you have the opportunity to optimise supply chain management, enhance inventory control systems, and improve product quality control measures. By reengineering processes, you can identify bottlenecks, inefficiencies, and areas for improvement, thereby paving the way for a more agile and competitive food manufacturing operation.

BPR enables you to adapt quickly to changing consumer demands, market trends, and regulatory requirements, ensuring that your food manufacturing processes remain efficient and responsive in a dynamic environment.

Advantages

Operational efficiency and effectiveness can be elevated through the strategic implementation of Business Process Reengineering (BPR) in food manufacturing. By reevaluating and redesigning processes from end to end, BPR offers several advantages to food manufacturing companies.

Firstly, BPR can lead to significant cost reductions by streamlining operations, eliminating redundant steps, and automating manual tasks. This efficiency improvement not only lowers production costs but also enhances overall profitability.

Secondly, BPR enhances quality control by focusing on process standardisation and optimisation. Through the reengineering of processes, companies can ensure consistency in product quality and reduce the risk of errors or defects.

Additionally, BPR promotes innovation and agility within food manufacturing organisations. By encouraging a fresh perspective on existing processes, companies can adapt more quickly to market changes, consumer demands, and technological advancements.

Limitations

Implementing Business Process Reengineering (BPR) in food manufacturing can present challenges that hinder its effectiveness and success. One limitation of BPR is the resistance to change from employees who may feel threatened by the restructuring of processes. This resistance can lead to low morale, decreased productivity, and ultimately, the failure of the reengineering efforts.

BPR requires significant time, resources, and expertise to implement successfully, which some organisations may struggle to allocate. The complexity of food manufacturing processes can also pose a limitation, as it may be difficult to accurately map out and optimise these intricate processes effectively.

The fast-paced nature of the food industry can make it challenging to sustain the improvements brought about by BPR in the long term. Therefore, while BPR offers significant benefits in streamlining operations and enhancing efficiency, these limitations must be carefully considered and addressed to ensure its successful implementation in food manufacturing.

Product Life Cycle Management (PLM)

We’ll explore the definition, applications in food manufacturing, as well as the advantages and limitations of Product Life Cycle Management (PLM) in the food industry.

Understanding how PLM functions within the context of food manufacturing can provide valuable insights into optimising product development processes.

Definition

Product Life Cycle Management (PLM) involves overseeing the entire lifespan of a food product, from concept development to disposal. It’s a strategic approach that focuses on maximising the value of a product throughout its existence.

PLM encompasses various stages, including design, manufacturing, marketing, and end-of-life considerations. The primary goal of PLM is to optimise processes, reduce time to market, and enhance product quality.

Within food manufacturing, PLM plays a crucial role in ensuring that products meet consumer demands, regulatory requirements, and industry standards. By implementing PLM practices, food manufacturers can streamline operations, improve collaboration among teams, and enhance innovation.

Through effective PLM, companies can better manage product data, track changes, and make informed decisions throughout the product life cycle.

In essence, Product Life Cycle Management in food manufacturing is about more than just creating a product; it’s about orchestrating a holistic approach that considers every phase of a product’s journey, from inception to retirement.

Applications in Food Manufacturing

Effective management of the product life cycle in food manufacturing involves strategically overseeing every stage of a food product’s existence, from initial development to disposal. Product Life Cycle Management (PLM) is crucial for ensuring that food products meet quality standards, regulatory requirements, and consumer demands throughout their lifespan.

In food manufacturing, PLM begins with research and development, where new product ideas are tested and refined before moving into production. Once a product is launched, PLM focuses on optimising production processes, maintaining consistent quality, and adapting to market changes.

During the growth phase, marketing strategies are implemented to increase product awareness and market share. As products mature, cost efficiencies become paramount to sustain profitability. Towards the end of a product’s life cycle, decisions must be made regarding potential upgrades, line extensions, or discontinuation.

Proper management of the product life cycle in food manufacturing enables companies to innovate, remain competitive, and meet sustainability goals.

Advantages

Implementing Product Life Cycle Management (PLM) in food manufacturing offers numerous advantages for companies seeking to optimise their operations and stay competitive in the market.

Firstly, PLM helps streamline the product development process by providing a centralised platform for collaboration among different departments, leading to faster innovation and time-to-market. This efficiency translates to cost savings as companies can reduce waste and minimise errors throughout the product life cycle.

PLM enables better record-keeping and compliance with regulations by maintaining detailed records of each stage of a product’s life, from conception to disposal. This enhanced visibility not only ensures quality and safety but also builds consumer trust.

By facilitating data-driven decision-making, PLM empowers companies to identify market trends, anticipate consumer demands, and adapt their products accordingly to meet changing preferences.

Limitations

Consider the challenges that arise when utilising Product Life Cycle Management (PLM) in food manufacturing. One major limitation is the complexity of managing multiple products simultaneously within the PLM system. Coordinating the various stages of different products’ life cycles can become overwhelming, leading to potential errors or delays in product development.

Integrating PLM approaches with existing systems can be a daunting task. Compatibility issues may arise, requiring time-consuming adjustments to ensure smooth data flow.

Another limitation is the high initial investment required for implementing PLM in food manufacturing. Small to medium-sized companies may find it financially burdensome to adopt PLM technology, limiting their ability to compete with larger corporations that can afford robust PLM systems.

Theory of Constraints (TOC)

You’re about to explore the Theory of Constraints (TOC) in food manufacturing.

Understand its definition, applications in the industry, as well as its advantages and limitations.

This discussion will provide you with valuable insights into how TOC can impact food manufacturing processes.

Definition

In food manufacturing, the Theory of Constraints (TOC) is a management approach that focuses on identifying and alleviating bottlenecks in production processes. TOC is based on the idea that every process has a constraint that limits the overall output or efficiency. By pinpointing these constraints, whether they’re related to equipment, manpower, or processes, TOC aims to optimise the flow of production and improve overall performance.

The primary goal of TOC is to enhance throughput, reduce inventory, and minimise operating expenses by strategically managing the constraints within the system. Through the application of TOC principles, food manufacturers can streamline operations, increase productivity, and ultimately boost profitability. TOC emphasises the importance of constantly reassessing and adjusting production processes to adapt to changing demands and constraints.

Applications in Food Manufacturing

By focusing on optimising the constraint, whether it be a machine, process, or resource that limits overall throughput, you can significantly improve the flow of production.

TOC emphasises the importance of synchronising operations to the pace of the constraint to prevent overburdening or underutilising it. This approach helps in maximising the overall output of the manufacturing process.

TOC advocates for reducing work in progress (WIP) inventory to prevent excess materials from piling up before the constraint, which can lead to inefficiencies and increased lead times. By managing inventory levels effectively and ensuring a steady flow of materials to the constraint, you can enhance production efficiency and minimise waste in the food manufacturing process.

In essence, the Theory of Constraints provides a structured methodology for identifying, managing, and improving the critical bottlenecks in food manufacturing, ultimately leading to enhanced productivity and profitability.

Advantages

Maximising production efficiency and streamlining operations are key advantages of implementing the Theory of Constraints (TOC) in food manufacturing. By identifying and addressing bottlenecks within the production process, TOC helps you optimise resource utilisation and enhance overall productivity.

With a clear focus on enhancing throughput, TOC enables you to prioritise tasks effectively, ensuring that critical processes are given the necessary attention to prevent delays and improve overall flow.

TOC fosters a more strategic approach to decision-making by emphasising the importance of synchronising different stages of production. This synchronisation not only reduces lead times but also minimises inventory levels, ultimately leading to cost savings and improved profitability.

The Theory of Constraints encourages a holistic view of the manufacturing process, promoting a systemic understanding of how each component contributes to the overall success of the operation.

In essence, the implementation of TOC in food manufacturing empowers you to operate more efficiently, reduce waste, and achieve higher levels of customer satisfaction through timely delivery of high-quality products.

Limitations

Implementing the Theory of Constraints (TOC) in food manufacturing may present challenges that hinder its full effectiveness. The complexity of food manufacturing processes can make it challenging to identify the true constraints accurately. This can lead to misallocation of resources and efforts, undermining the intended benefits of TOC implementation.

Another limitation is the potential for tunnel vision. Focusing solely on alleviating constraints may cause other areas of the operation to be neglected, leading to inefficiencies overall. Moreover, the success of TOC relies heavily on the accuracy and timeliness of data collection. Inaccurate or outdated information can misguide decision-making, impacting the effectiveness of TOC strategies.

Despite these limitations, addressing them proactively through proper training, communication, and data management can help maximise the benefits of TOC in food manufacturing.

Supply Chain Management (SCM)

Let’s kick off the discussion on Supply Chain Management (SCM) by exploring its definition, applications in food manufacturing, as well as its advantages and limitations.

Understanding how SCM plays a crucial role in optimising the flow of goods and information throughout the food manufacturing process is key to enhancing efficiency and reducing costs.

Definition

Supply Chain Management (SCM) involves the coordination of activities to ensure the seamless flow of goods and services from raw material suppliers to end customers. It encompasses the planning, execution, control, and monitoring of supply chain activities to create value for customers while optimising costs.

SCM focuses on integrating key business processes like production, inventory management, logistics, and distribution to enhance efficiency and customer satisfaction.

Effective SCM necessitates collaboration among suppliers, manufacturers, distributors, and retailers to streamline operations and meet consumer demands. It involves managing the entire lifecycle of a product, from sourcing raw materials to delivering the final product to consumers.

By implementing SCM practices, companies can improve inventory management, reduce lead times, minimise costs, and enhance overall supply chain performance.

In essence, SCM plays a crucial role in ensuring that the right products are available at the right time, in the right quantities, and at the right locations to meet customer needs effectively. It’s a fundamental aspect of modern business operations, particularly in industries like food manufacturing where timely delivery and quality are of paramount importance.

Applications in Food Manufacturing

Efficiently managing the supply chain in food manufacturing involves orchestrating the seamless flow of raw materials and products to ensure timely delivery and quality for consumers. In SCM, you must coordinate activities such as sourcing raw ingredients, production, storage, and distribution to meet consumer demand. By implementing effective supply chain strategies, you can minimise waste, reduce costs, and enhance overall efficiency in your food manufacturing processes.

Utilising technology like inventory management systems and real-time tracking tools enables you to monitor the movement of goods throughout the supply chain accurately. This visibility helps in identifying potential bottlenecks or delays, allowing you to take proactive measures to address them promptly. Additionally, establishing strong relationships with suppliers and distributors is crucial for maintaining a reliable supply chain network.

Furthermore, implementing just-in-time inventory practices can help streamline operations by ensuring that materials are delivered precisely when needed, reducing excess inventory holding costs.

Advantages

Embracing Supply Chain Management (SCM) brings numerous advantages that can revolutionise your operations and boost overall efficiency and help to optimise your food manufacturing processes. By implementing SCM practices, you can enhance coordination between different stages of production, from sourcing raw materials to delivering the final product.

This improved coordination leads to reduced lead times, minimising delays and ensuring a more streamlined production flow. SCM also enables better inventory management, helping you maintain optimal stock levels and prevent excess or insufficient inventory situations.

SCM facilitates better communication and collaboration with suppliers and distributors, fostering stronger relationships and ensuring timely deliveries. This increased transparency across the supply chain enhances responsiveness to changes in demand and market conditions, allowing for quicker adaptations and improved customer satisfaction.

Implementing SCM can lead to cost savings through reduced waste, improved resource utilisation, and minimised transportation expenses. Overall, embracing Supply Chain Management in your food manufacturing processes can result in increased efficiency, cost-effectiveness, and competitiveness in the market.

Limitations

Despite its numerous advantages, Supply Chain Management (SCM) in food manufacturing also presents certain limitations that warrant consideration. One significant limitation is the complexity of managing multiple stakeholders across the supply chain. Coordinating activities between suppliers, manufacturers, distributors, and retailers can be challenging, especially when each entity operates independently with different goals and priorities. This complexity can lead to communication breakdowns, delays in decision-making, and difficulties in aligning strategies.

Another limitation of SCM in food manufacturing is the risk of supply chain disruptions. External factors such as natural disasters, political instability, or global pandemics can severely impact the flow of goods and materials, causing delays or shortages in production. Without robust contingency plans in place, these disruptions can have far-reaching consequences on the entire supply chain, affecting product availability.

The reliance on technology and data in SCM can be a limitation for some food manufacturers. Implementing and maintaining sophisticated systems for inventory management, demand forecasting, and logistics can be costly and require specialised expertise. Additionally, cybersecurity threats pose a risk to sensitive supply chain data, potentially leading to breaches or system failures.

In Summary

Integrating various management concepts and approaches in food manufacturing is really helpful for optimising operations, driving success, and staying competitive in the industry.

By utilising tools like SWOT analysis, PEST analysis, Porter’s Five Forces, Six Sigma, Lean Management, and others, companies can enhance efficiency, quality, and innovation in their processes and products.

Embracing these methodologies will help food manufacturers navigate challenges, capitalise on opportunities, and achieve sustainable growth.

Further Resources

Food Industry Hub serves the food industry with a range of digital resources for the benefit of both commercial food manufacturers and food industry professionals.

For food manufacturers, we offer integrated management systems that give every user a direct interface with your QMS.

For food industry professionals, we provide an extensive signposting service in addition to informational content we hope you’ll find useful as you face new professional challenges. We have very ambitious plans to expand the range of services offered, and currently present informational content on management, safety and quality, food safety and quality culture, and professional success.